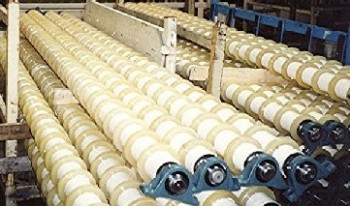

If you have a production line, you likely have a lot of rolls moving product down it. Many production lines run 24/7, taking a heavy toll on your rolls. When they get worn out you can either replace them or refurbish them. Rebuilding rolls is usually more cost-effective than installing new rolls as well as more environmentally friendly. We can provide you with both services.

If you have a production line, you likely have a lot of rolls moving product down it. Many production lines run 24/7, taking a heavy toll on your rolls. When they get worn out you can either replace them or refurbish them. Rebuilding rolls is usually more cost-effective than installing new rolls as well as more environmentally friendly. We can provide you with both services.

We have been rebuilding rolls since the founding of our company, rejuvenating thousands of rolls of all types including those with finned rubber tires, urethane donuts, solid Carbox/Kevlar, Neoprene, rubber O-Rings and other types. We make sure that the roll surface meets your size and durometer needs. We can also supply your mechanical roll with the bearings, sheaves and gears included, ready to install on your line. We have an extensive network of sources for roll-end hardware. If we can't find the part needed, we will make it.

During

roll rebuild, we begin by measuring surface dimensions, tire and hardware placement and gathering all the information to re-create each roll. Your rolls are then stripped and cleaned. If existing roll end parts are to be re-used, they are cleaned and checked to make sure they are functioning properly and are within tolerance. Roll journals and shaft keyways are likewise checked. When journal or keyway repair is required, they are professionally fabricated and machined. If necessary, rolls are center-drilled for machining. Rolls which are outside of your straightness tolerance requirements are straightened.

roll rebuild, we begin by measuring surface dimensions, tire and hardware placement and gathering all the information to re-create each roll. Your rolls are then stripped and cleaned. If existing roll end parts are to be re-used, they are cleaned and checked to make sure they are functioning properly and are within tolerance. Roll journals and shaft keyways are likewise checked. When journal or keyway repair is required, they are professionally fabricated and machined. If necessary, rolls are center-drilled for machining. Rolls which are outside of your straightness tolerance requirements are straightened.

Rolls with pressed on tires can be glued in place when required for your application. Solid cover rolls have the covering replaced. Once roll surfacing is complete and verified to be within tolerance, all gearing, sheaves and bearings are installed as specified. Roll surfaces can also be painted when desired.

Each roll is then wrapped to protect it in preparation for delivery. Any markings or labels you require for reference are applied.

Roll Ordering

Roll OrderingBecause your company's requirements are unique and the rolls need to be finished in materials that meet your particular needs, we ask that you contact us so that we can work with you to tailor our service to your needs.

Shipping Information

All Pricing FOB Carleton, Michigan US. Note that all shipped orders will have an additional charge for the purchase of a custom-built shipping box.

Overseas Customers

Please contact us to discuss shipping options. Note that we require payment in advance for new oversea customer orders.

Below are some examples of rolls we have rebuilt for customers like you.